Product Details:

| Place of Origin: | Mold Controller Manufacturer |

| Brand Name: | AODE |

| Certification: | ISO, CE, ROHS |

| Model Number: | ARD-30 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | $ |

| Packaging Details: | Protective/air bubble film, Wooden case. As client’s require |

| Delivery Time: | Within 20days after receiving |

| Payment Terms: | 30% T/T in advance, 70% balanc |

| Supply Ability: | 500pcs/month |

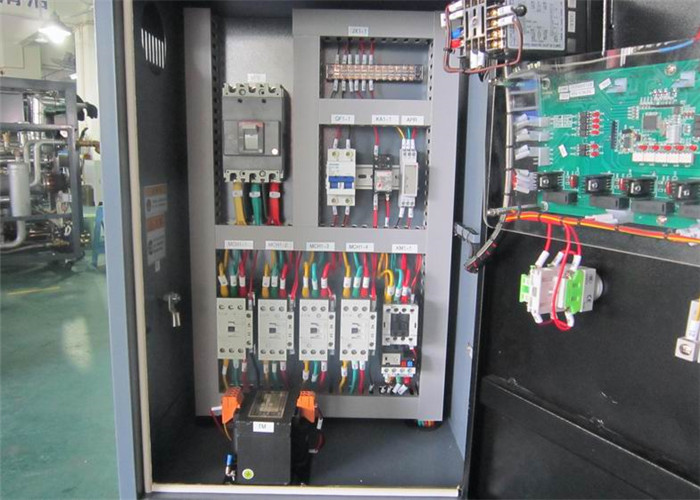

Industrial Water Mold Temp Controller ARD-30 for Injection Molding with PID ±1℃ Accuracy is one type of our AODE's mold temp controllers, this Mold Temp Controller is a high-precision industrial water-based unit designed for plastic injection molding, rubber, film, and mold manufacturing. It features a PID control accuracy of ±1℃, temperature range from 15℃ to 98℃, and a powerful 36KW heating system with a 2.2KW pump delivering stable 2.2Kg/cm² pressure. With built-in alarms for pump reversal, water shortage, overheating, and overload, it ensures operational safety. Easy to maintain and customizable, it enhances production efficiency and product quality.

| Product Name: | industrial water mold temp controller for injection molding | Brand Name: | AODE |

|---|---|---|---|

| Application: | Plastic Injection Molding, Chemical | Certification: | CE, ISO |

| Cooling Method: | Indirect Cooling | Heat Transfer Medium: | Water |

| Power Supply: | AC3∮380V | Temp Control Accuracy: | PID±1℃ |

| Temperature Range: | 15℃-98℃ | ||

| High Light: | industrial water mold temp controller, mold temp controller for injection molding, mold temp controller with PID ±1℃ Accuracy | ||

|

|

The ARD-30 mold temp controller helps stabilize production processes, improve molded product quality, and reduce scrap rate and downtime. With smart safety functions, high durability, and customization flexibility, it's a valuable investment for enhancing automation and precision in manufacturing.

ITEM | UNIT | ARD-30 |

Temp control range | ℃ | Inlet water temperature +15℃-98℃ |

Temp control accuracy | ℃ | PID±1℃ |

Power supply | AC3∮380V 50HZ 3P+E(5M) | |

Heat transfer medium | Water | |

Cooling method | Direct Cooling(indirect cooling can be customized) | |

Heating capacity | KW | 36 |

Pump power | KW | 2.2 |

Pump flow | L/min | 150 |

Pump pressure | Kg/cm2 | 2.2 |

Max. power consumption | KW | 40 |

Alarm function | Pump reversal/Water shortage/Overheating/Overload | |

Cooling water pipe | inch | 1/2 |

Circulating water pipe | inch | 3/4 |

Size(L×W×H) | mm | 1150×500×1000 |

Applications of mold temp controllerPlastic injection molding Rubber processing Film production Mold manufacturing Light guide plate production Electronic connector molding | Customization Options of mold temp controllerCustom heating power and pump horsepower Direct or indirect cooling modes Explosion-proof electrical box Multi-point temperature control system PLC or microcomputer control RS485 communication function Rapid shutdown cooling Thick copper piping (1.0–1.2mm) |

A mold temperature controller with PID ±1℃ accuracy ensures precise and stable temperature control throughout the injection molding process. This precision reduces defects like warping, shrinkage, or burns on molded parts, while improving product consistency and surface quality. Accurate temperature control also shortens cycle time, reduces energy consumption, and enhances mold protection. It is especially valuable for high-precision or thin-walled plastic products, making it an essential tool for manufacturers seeking high efficiency and product quality.

Installation Steps:

| Operation Instructions:

| Safety Guidelines:

|

| Installation Support | Step-by-step video, documentation, optional on-site support |

| Operation Training | User manual, remote training via video call |

| Maintenance Support | Scheduled maintenance guide, alarm diagnosis support |

| Spare Parts Supply | Long-term availability of key components like pump, heater, control board |

| Troubleshooting | 24/7 online support, remote diagnostics, service hotline |

| Warranty & Service | 1-year warranty with optional extended service contracts |

The high precision of ±1℃ ensures stable mold temperatures, preventing defects such as shrinkage or deformation. It improves product consistency, especially for complex or precision parts.

This mold temp controller includes alarms for overheating, pump reversal, water shortage, and overload. It also has short circuit protection and automatic cooling shutdown for enhanced safety.

Simply set your target temperature using the control panel. The system automatically adjusts heating and cooling with real-time monitoring and alarm functions to ensure safe operation.

It offers 36KW heating capacity, 2.2KW pump, PID accuracy, indirect/direct cooling, automatic air exhausting, optional RS485 communication, and stainless-steel pipe system for durability.

Yes. Customization options include pump size, heating power, multi-point control, explosion-proof design, and remote communication features like PLC or RS485 for automation integration.

It offers long service life with up to 10 years of use when properly maintained. Maintenance is simple—regular pipe checks, water filtration, and system flushing ensure optimal performance.

Address: No.37,Dayang Industrial Area, Xingang East Road, Lougang Boulevard, Songgang Town, Bao'an District, Shenzhen