Product Details:

| Place of Origin: | Mold Controller Manufacturer |

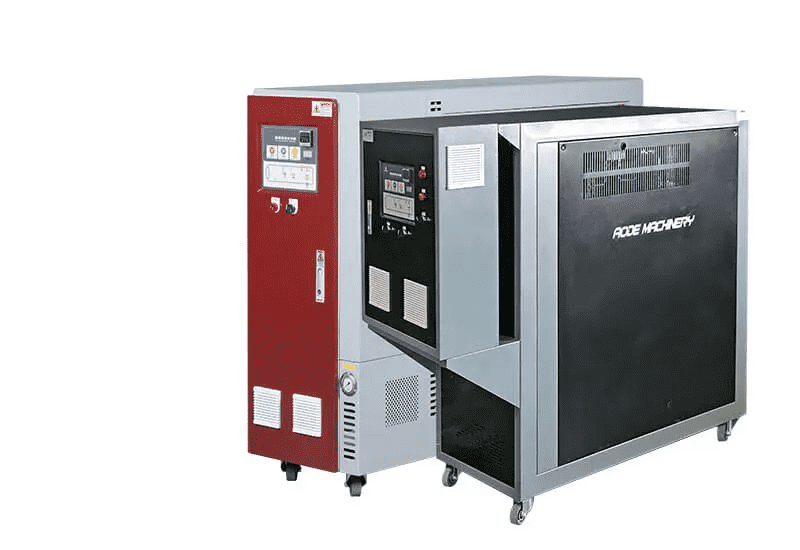

| Brand Name: | AODE |

| Certification: | ISO, CE, ROHS |

| Model Number: | AGBT-40-10 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | $ |

| Packaging Details: | Protective/air bubble film, Wooden case. As client’s require |

| Delivery Time: | Within 20days after receiving |

| Payment Terms: | 30% T/T in advance, 70% balanc |

| Supply Ability: | 500pcs/month |

High-Temperature Oil Temperature Control Unit is designed to deliver precise thermal regulation for high-temperature industrial applications. With a temperature control range of +25℃ to 400℃ for oil, it provides exceptional stability for processes requiring consistent heat. This oil temperature control unit features PID ±1℃ control accuracy, customizable heating capacities up to 240KW, pump power 1.5 2.2 3 4 5 KW, and explosion-proof options, making it ideal for demanding applications like die casting, injection molding, and aerospace parts manufacturing. It offers energy efficiency, improved operational safety, and reduced downtime, contributing to enhanced production efficiency and cost savings.

|

|

ITEM | UNIT | Model | |||||||

| AEOT-20 | AEOT-30 | AEOT-40 | AEOT-50 | AEOT-75 | AEOT-100 | AEOT-150 | AEOT-200 | ||

| Temp control range | ℃ | Inlet water temperature +45℃-300℃ | |||||||

| Temp control accuracy | ℃ | PID±1℃ | |||||||

| Power supply | 3N-380V-50Hz | ||||||||

| Heat transfer medium | Thermo conductive oil | ||||||||

| Cooling method | Indirect Cooling | ||||||||

| Expansion tank capacity | L | 24 | 67 | 67 | 67 | 100 | 150 | 200 | 300 |

| Heating capacity | KW | 12/24 | 30/36 | 60 | 60 | 60/90 | 90/120 | 120/180 | 180/240 |

| Pump power | KW | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Pump flow | m³/h | 6.5 | 10 | 12.5 | 16 | 12.5 | 25 | 45 | 50 |

| Pump pressure | m | 28 | 31 | 32 | 32 | 50 | 54 | 42 | 50 |

| Max. power consumption | KW | 25.5 | 38.2 | 63 | 64 | 95.5 | 127.5 | 191 | 255 |

| Alarm function | Inverse phase/Oil Shortage/Overheating/Overload/Oil Overflow/Abnormal Heating | ||||||||

| Cooling water pipe | inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | / | / | / |

| Circulating water pipe | inch | 1 | 1 | 1 | 1 | 1 | 1 | 1.5 | 2 |

| Size(L×W×H) | mm | 1200*440*1100 | 1470*500*1250 | 1720*550*1350 | 1720*550*1350 | 1690*600*1500 | 1690*600*1500 | 1780*650*1800 | 1750*800*1800 |

Remark: We reserve the rights to change the parameters without notice, special specifications can be customized

The High-Temperature Oil Temperature Control Unit works by circulating heated oil through the system to maintain the desired temperature in molds, reactors, or other equipment. The system features advanced microcomputer or PLC controls to ensure precise temperature management. The built-in pump circulates the heat transfer oil, maintaining an optimal thermal environment. The integrated safety features, including alarm functions for overheating and oil shortages, ensure reliable and safe operation.

Compared to standard oil temperature control unit, the High Temperature Oil Temperature Control Unit offers a broader temperature range of up to 400℃, making it suitable for more extreme industrial applications. It also includes customizable pump capacities and specialized features such as explosion-proof and cooling options to meet higher safety and performance standards. These enhancements make it the ideal solution for industries where precise and stable high-temperature control is critical.

Opportunities:

| Challenges:

| ROI & Payback Period:

|

Applications | Advantages | Customization Options |

| - Injection molding | - High-temperature control up to 400°C | - Customizable pump power and heating capacity |

| - Die casting of metals like aluminum, zinc, and magnesium | - High accuracy with PID control ±1°C | - Multi-point temperature control |

| - Rubber and plastic processing | - Increased efficiency and energy savings | - Explosion-proof models available |

| - Aerospace and automotive component manufacturing | - Reliable safety features (oil shortage, overheating, etc.) | - RS485 communication for integration with monitoring systems |

| - Chemical reactors and pharmaceutical manufacturing | - Low maintenance and easy repair due to modular design | - Optional cooling functions (shutdown delay, blowing back oil) |

| - High-speed rail component production | - Provides stable heat distribution and reduced thermal fluctuation | - Adjustable temperature range and control system options |

| Step | Action | Details |

|---|---|---|

| 1. Installation | - Ensure correct voltage supply (3N-380V-50Hz) | - Install unit on level ground, connect power and circulation pipes |

| 2. Configuration | - Set the desired temperature range and PID control settings | - Customize pump power, expansion tank capacity, and heating capacity |

| 3. Operational Setup | - Connect to external systems if needed (e.g., POS or controllers) | - Follow on-screen guide or manual for system initialization |

| 4. Testing | - Run a test cycle to confirm proper functioning | - Ensure there are no leaks, check oil levels, and monitor temperature fluctuations |

| 5. Final Check | - Verify alarm functions and safety measures | - Test emergency shutdown and overheating functions |

| 1. Proper Installation | - Ensure correct pipe connections and power supply. |

| 2. Regular Maintenance | - Clean the system and check for oil degradation regularly. |

| 3. Safety Monitoring | - Check for oil overflow, overheating, and pressure issues. |

| 4. Avoid Overloading | - Do not exceed specified power or temperature limits. |

| 5. Oil Replacement | - Replace oil as recommended to maintain system performance. |

The High-Temperature Oil Temperature Control Unit offers a wide temperature control range from +25°C to 400°C for oil and +25°C to 180°C for water. This flexibility allows it to handle a variety of high-temperature applications, such as injection molding, die casting, and chemical reactions, providing precise control over thermal processes.

With its PID ±1°C temperature accuracy and stable heat distribution, the High-Temperature Oil Temperature Control Unit ensures high precision in controlling temperatures. This reduces production errors, enhances process stability, and shortens cycle times, leading to improved operational efficiency and reduced costs in industrial applications.

The unit comes equipped with multiple safety functions, such as overheating protection, oil shortage alarms, and overload safeguards. Additionally, it features a fault display system for easy maintenance and troubleshooting. These safety measures help prevent equipment damage and ensure smooth, secure operation in demanding environments.

The unit is pre-configured by the manufacturer. To set up, connect it to the power supply (3N-380V-50Hz) and circulation pipes. Customize settings, such as temperature range and PID control, according to your process requirements. Follow the on-screen instructions or manual for easy startup. Ensure all components are securely installed and tested.

The pump power ranges from 1.5KW to 15KW depending on the model, offering flexibility to meet specific application needs. Heating capacity is customizable, with units available from 12KW up to 240KW. This allows businesses to choose the optimal configuration based on production scale and thermal requirements.

Common applications include injection molding, die casting of metals like aluminum, magnesium, and zinc, rubber and plastic processing, aerospace manufacturing, and chemical reactors. It is especially effective in processes requiring precise high-temperature control and consistent thermal stability for enhanced product quality.

To purchase, contact the manufacturer or authorized distributors such as AODE Machinery Co., Ltd. Provide details of your application, preferred configuration, and capacity requirements. They will offer a suitable solution based on your needs and provide pricing information. Ensure to inquire about after-sale support and warranty options.

Regular maintenance includes cleaning the system, checking oil levels, replacing oil as per the manufacturer’s guidelines, and performing periodic software updates. It is essential to inspect the pump and heating elements for wear and ensure there are no leaks or pressure issues to avoid costly repairs and downtime.

Address: No.37,Dayang Industrial Area, Xingang East Road, Lougang Boulevard, Songgang Town, Bao'an District, Shenzhen